Mechanical Marvels: a middle school studio

Our middle school students dove deep into studio exploration where they specialized in a craft intended to expand their tools of expression!

The Mechanical Marvels Studio was an opportunity for students to acquire basic skills with 3d design software, laser cutting, and CNC milling. In addition, teamwork was emphasized and giving and receiving constructive feedback was modeled.

The first task was one involving teamwork: the studio split into two groups and designed and built shelves on which to store their future works in progress. The second task similarly involved teamwork, but with different team compositions; it was thinking about an axle mechanism that could work with gearing. These tasks required no new skills of the students, but gave the studio host an opportunity to see what they knew, and how they worked individually and in groups.

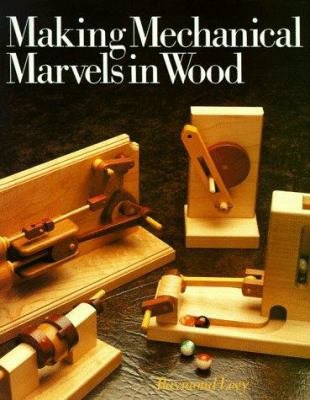

Following that, they were introduced to Rhino (3d design software) and to related tools for generating gears in Rhino. They then looked through a catalog of mechanical mechanisms and each selected one that they wanted to make. They then designed the mechanisms, laser cut prototypes from corrugated cardboard, adjusted the designs as necessary, then milled the components of the mechanisms from 12mm Baltic birch on the CNC mill. For this exercise, the studio host provided specifications for the gears (all gears had to have a module of 6 and at least ten teeth) and the design for (and 3d prints of) the hubs and axles on which the gears would turn.

This spanned the first four weeks of studio. In the second half of studio the students had the opportunity to design and build a mechanical iris either individually or in teams. They chose to work in one team, and after making prototypes from existing iris designs to learn how mechanical irises work, they chose to divide the work by having each student design one part of the mechanism, with one student assembling the mechanism at the end of the process.